Process Orders: Difference between revisions

Created page with "A Process Order is also sometimes known as a Works Order depending on the system. The purpose of such an order is simply an instruction to make something. Typically an order will contain the material code of the output product/material, the unit of measure used to record the production and a quantity of units required. 600px You should note that there is an interface available within Commander4j to import Process Order data from an external..." |

No edit summary |

||

| (2 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[Category: Commander4j]] | |||

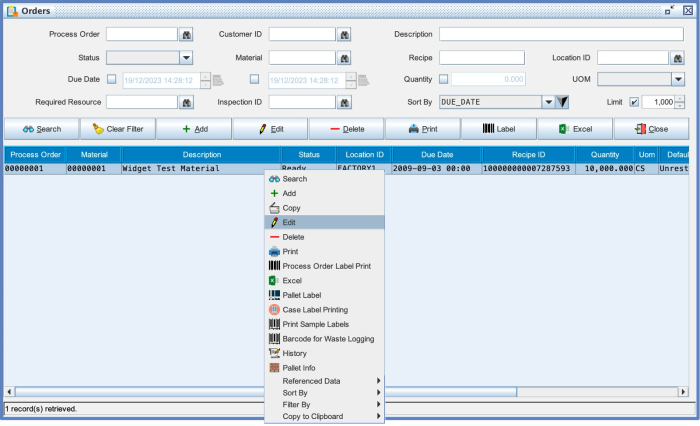

A Process Order is also sometimes known as a Works Order depending on the system. The purpose of such an order is simply an instruction to make something. Typically an order will contain the material code of the output product/material, the unit of measure used to record the production and a quantity of units required. | A Process Order is also sometimes known as a Works Order depending on the system. The purpose of such an order is simply an instruction to make something. Typically an order will contain the material code of the output product/material, the unit of measure used to record the production and a quantity of units required. | ||

[[file:Process order1.png| | [[file:Process order1.png|link=|700px]] | ||

You should note that there is an interface available within Commander4j to import Process Order data from an external system using an XML message. You can however create the order manually. | You should note that there is an interface available within Commander4j to import Process Order data from an external system using an XML message. You can however create the order manually. | ||

| Line 7: | Line 8: | ||

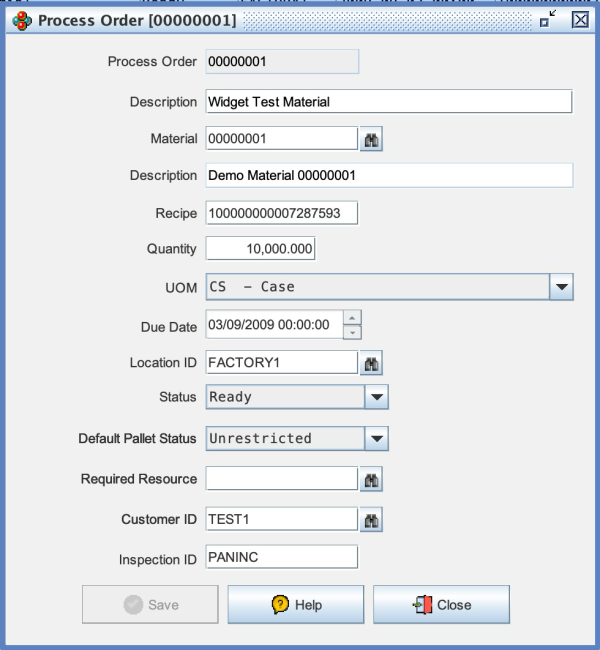

The screen below shows the fields which are available within the order. | The screen below shows the fields which are available within the order. | ||

[[file:Process order2.png|600px]] | [[file:Process order2.png|link=|600px]] | ||

The customer ID can be populated with "SELF" if your making product for your own brand. However it's also possible that you maybe making product for another customer. By specifying a customer code here you can influence the way that the labels are printed. If you check the [[Customers]] module you will see there are options to override the Pallet and Case Labels and choose an alternative batch format. | The customer ID can be populated with "SELF" if your making product for your own brand. However it's also possible that you maybe making product for another customer. By specifying a customer code here you can influence the way that the labels are printed. If you check the [[Customers]] module you will see there are options to override the Pallet and Case Labels and choose an alternative batch format. | ||

There is a field called [[Required Resources]] which is typically used to identify some part of the factory which is being used to make this particular order. For example you might setup resouces called "LINE1", "LINE2" etc. | There is a field called [[Required Resources]] which is typically used to identify some part of the factory which is being used to make this particular order. For example you might setup resouces called "LINE1", "LINE2" etc. | ||

Latest revision as of 14:30, 2 September 2024

A Process Order is also sometimes known as a Works Order depending on the system. The purpose of such an order is simply an instruction to make something. Typically an order will contain the material code of the output product/material, the unit of measure used to record the production and a quantity of units required.

You should note that there is an interface available within Commander4j to import Process Order data from an external system using an XML message. You can however create the order manually.

The screen below shows the fields which are available within the order.

The customer ID can be populated with "SELF" if your making product for your own brand. However it's also possible that you maybe making product for another customer. By specifying a customer code here you can influence the way that the labels are printed. If you check the Customers module you will see there are options to override the Pallet and Case Labels and choose an alternative batch format.

There is a field called Required Resources which is typically used to identify some part of the factory which is being used to make this particular order. For example you might setup resouces called "LINE1", "LINE2" etc.